RFID evolution enables smarter tracking

Did you know the origins of RFID technology can be traced to WWII? However, RFID as a technology only started to gain any recognition in product surveillance tags during the 1960s. Since then, RFID’s popularity has shown no signs of dimming. Used in any situation that requires contactless and non-line-of-sight identification of an individual object, RFID systems are now found at the heart of most supply chains.

But the RFID tag of today looks somewhat different to the entirely passive, low frequency versions of a couple of decades ago and it’s set for further evolution. RFID systems are beginning to incorporate previously unthinkable levels of information on the goods, animals or people being tracked, facilitating ever more complex supply chains.

One example is an RFID tag with integrated temperature sensor, used to track the transportation conditions of food and medicine. The system in question performs regular measurements to verify that supply chain requirements have been met throughout the product’s journey. Previously, spot checks were made using data loggers, but this only provided a snapshot of conditions. In this way, RFID technology is transforming the transport of goods, resulting in higher product safety and less manual interaction with the goods. The same principle is being applied towards integrating other ultra-low power sensors, with strain, crack, corrosion, moisture, gas and blood glucose, all perfect candidates for sensing.

Besides supply chain management, RFID has a key role to play in the manufacturing plant itself. Indeed, RFID promises to be one of the technologies that will drive the Industry 4.0 or ‘smart factory’ revolution. A key advantage of RFID technology in the manufacturing environment is that it enables mass customisation.

Everything from the morning cereal to motorbikes can be tuned to a customer’s preference. If you want more raisins in your muesli or a specific paint job, manufacturers are now beginning to let you do that as part of the ordering process. Without a technology like RFID, it is extremely difficult to support such a level of customisation. The manufacturer would need to synchronise multiple systems to make sure that a specific product moving through a factory receives the right mix of ingredients or treatments. With RFID tracking, the product itself can tell the machines and operators what it needs.

Typically, a product carrier contains the RFID tag into which is programmed a identifier at minimum. Potentially, the tag can store many other data items that may be used by machinery to optimise the product’s journey through the plant. In the case of custom cereal, when the carrier arrives at the raisin dispenser, the unit knows how much to add and mix. If the dispenser is unable to comply, it can write the error to the tag so that the product is not sent out incomplete. Barcodes, used in the past to support product customisation, are not as effective; RFID allows almost anything to be made ‘smart’.

There are a number of core requirements for industrial and supply chain RFID tags. The tag needs to be robust, offer consistent performance and be easy to apply to a product. There are standards that determine the level of performance needed from an RFID tag. The key standard for industrial applications is EPC Global Ultra High Frequency Gen 2. It can use a smaller antenna than the low- and high-frequency RFID technologies and offers a communications range from 0.5-8m depending on antenna design. The antenna structure is crucial to performance. Fortunately for OEMs and integrators, the high frequency of Gen2 communications makes it possible to incorporate the antenna in the same convenient package as the RFID interface and controller IC. This can make the solution much more robust than with a PCB-printed antenna and chip.

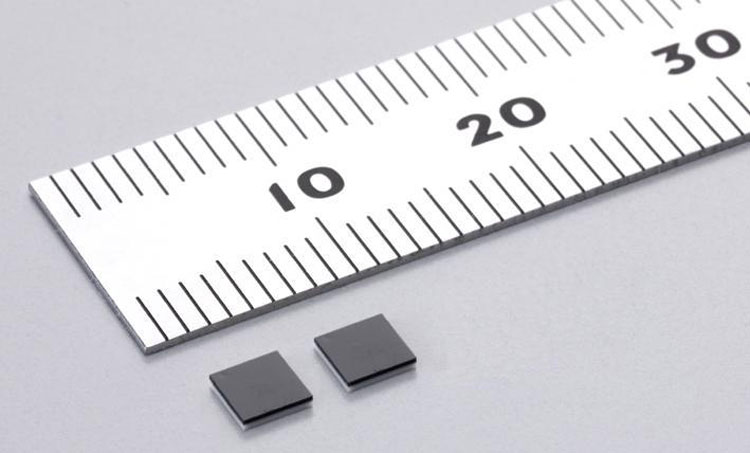

An example of a high integration Gen2 RFID device is Murata’s MAGICSTRAP. It contains a complete interface IC integrated with matching circuitry and antenna inside a low temperature co-fired ceramic (LTCC) and resin substrate. By providing the RF matching internally, the MAGICSTRAP device optimises power transfer between the IC and the customer antenna. The controller ICs can be multiple-sourced for maximum flexibility but with the same customer’s own preferred antenna pattern. The design uses inductive coupling between the antenna and the strap. In contrast to traditional RFID IC packages that need to be soldered to the PCB to provide an electrical connection, the MAGICSTRAP package needs only a mechanical connection, so that non-conductive epoxy can be used in place of solder.

Thanks to its design and attachment method, the MAGICSTRAP can withstand a 2kV ESD pulse. The tag also offers full-band impedance matching. This allows a single device to operate from 850-960MHz frequency covering all the recognised UHF bands used for RFID to support fully global operation.

Abracon provides a further range of package options based on ceramic packages and the choice of RFID ICs from leading providers Alien, Impinj and NXP. Abracon provides a number of standard designs to suit different supply chain RFID requirements supporting attachment to the product casing directly rather than a PCB. Tags can be attached directly to metal or embedded in the product’s surface, allowing maximum design flexibility.

Custom design options for the tag packages allow the integration of other devices alongside the RFID circuitry, supporting the inclusion of temperature sensors, additional memory and independent power sources for regular measurements.

Looking to the future, the combination of RFID tags with other technologies such as GPS location and/or LED displays will flourish. RFID tags with GPS have already been used in as diverse applications as cotton production and for tracking performance data in American football by integrating tags in the football and players shoulder pads.

Whatever your RFID project, Avnet Abacus’ comprehensive linecard includes RFID and near-field communication, wireless networking andGPS, sensors and displays, putting ourteam of technical specialists in a great position to support you withauthoritative advice on combining these technologies.

Click here for more information.