Wireless networking for the industrial IoT

Monitoring and measuring even very simple parameters improves processes, reduces downtime and saves money.

By Mike Fahrion, Director of Product Management, B&B Electronics.

Monitoring the condensate conductivity on a boiler can indicate the presence of a cooling water leak long before hydrogen embrittlement of the boiler’s furnace tubes causes it to fail. Measuring power consumption at a discrete level can reveal the precise energy cost of a specific process and predict mechanical failure if a particular machine suddenly begins to draw more electricity. Observing the temperature of a pump can alert an operator to shut it down before it overheats, and automatically shutting off the lights in a parking garage when no humans are present produces immediate savings in energy costs.

Unfortunately, many sensors need to do their jobs in locations that make wired data communications and AC power installations impractical. Even if the installation would be feasible and the costs would be reasonable, it’s not always possible to negotiate a right of way for the cabling. Fortunately, new technologies are coming on line that provide low-power wireless solutions that extend the network edge to include difficult locations while simultaneously providing ‘five nines’ (99.999%) uptime.

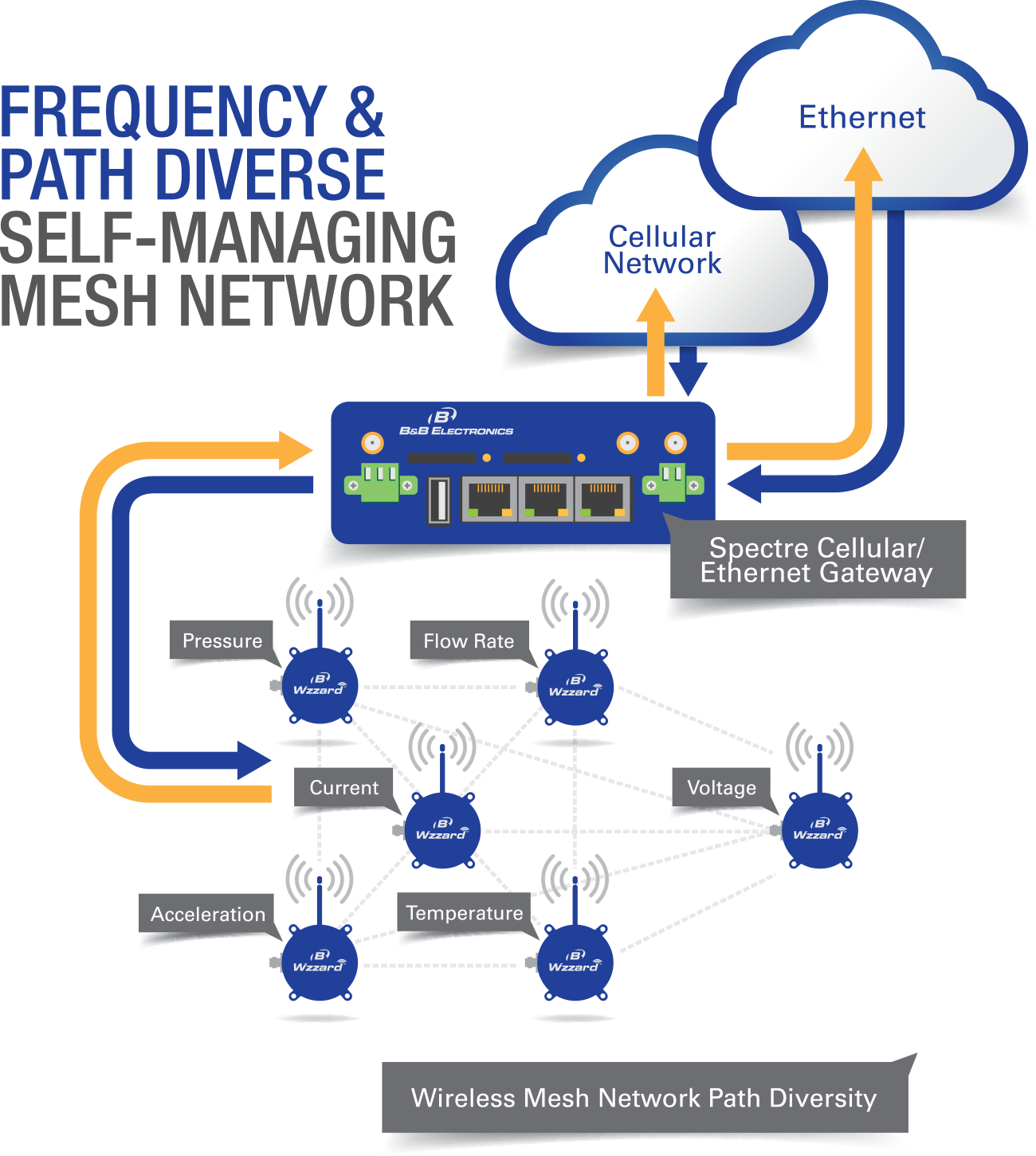

Figure 1 - Smart networks will be able to adapt to changing RF conditions

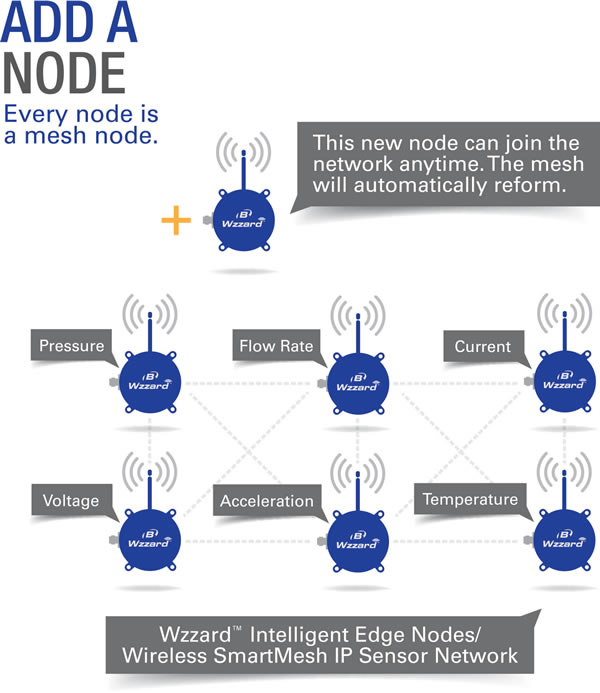

Based on the wireless IEEE 802.15.4e standard, SmartMesh IP mesh networks provide excellent connectivity for remote devices, even in harsh, dynamically changing RF environments (Figure 1). In a SmartMesh IP network, every node on the network serves as a router. The nodes can all communicate with one another, and also with the network gateway if the gateway is within range. Each node can receive data from any other network node that is within range, and transmit data to any other network node that is within range. If one path to the network gateway fails, the network nodes will reroute through another, for a frequency and path diverse self-managing mesh network. New nodes can be added or subtracted at any time, as the network is self-forming and self-healing (Figure 2). The end result is ‘five nines’ uptime for the network as a whole, even if communications through one of the individual nodes are temporarily blocked.

This also makes SmartMesh IP networks highly scalable. Devices can transmit data over long distances by passing data through intermediate devices to reach more distant ones. Thus, the network gateway doesn’t need to be within range of every device on the network. Full-featured network gateways can connect via wired connections or the cellular data networks, meaning that you can put them anywhere that you can get a cell phone signal. In situations where wired power connections are impractical, a cellular network gateway can use alternatives like solar.

When the network edge expands to include a location that is difficult to wire, power consumption inevitably becomes an important consideration. So remote network nodes will often need to be self-powered as frequent battery changes would be undesirable. One way to conserve power is to place some intelligence in the edge nodes themselves so that they will know precisely when to talk, listen, or sleep. This can involve networking tools like Time Synchronised Mesh Protocol (TSMP), a networking stack that includes a Time Slotted Channel Hopping (TSCH) media access layer. TSCH divides time into ‘slots’ and maps timeslots to channels with a pre-assigned hopping sequence. Packet exchanges are synchronised so they don’t collide on the network and every packet is scheduled and synchronised for energy efficiency with no extra preamble (Tx side) or guard interval time (Rx side). Nodes don’t have to waste time or power re-sending the same data again and again, and path rediscovery is not required.

Figure 2 - The ability to extend and modify wireless networks will be mandatory in the M2M era

Low power mesh networks can also use techniques like Message Queue Telemetry Transport (MQTT), an open source, lightweight publish/subscribe messaging protocol. Unlike traditional request-response protocols like HTTP or Modbus, MQTT minimises bandwidth and power needs by enabling a publish/subscribe messaging model. This reduces network traffic.

Putting mesh networks to work

There are countless applications for low power sensor networks and they can be used virtually anywhere there is a need for remote sensor deployment. Consider parking systems as just one example. No single technology is yet the best for every purpose, so parking systems tend to combine a wide array of equipment, multiple data networking protocols and multiple generations of technology. They can also run up a lot of unnecessary expenses. Is it really necessary to keep the lights on when no humans are actually present? Should power hungry ventilation fans keep running when vehicle emissions have fallen well below safe levels? A network that can monitor relevant environmental parameters and make useful decisions while simultaneously communicating with everything from card readers to security cameras can make the entire system more efficient.

Network nodes like gas detectors only need to report to the network when specified parameters are exceeded. Their bandwidth and power needs are quite small. If they’re smart enough to know when to report and when to sleep, there’s no reason they can’t be battery-powered and wireless. They would be good candidates for low power wireless mesh networking. A security camera transmitting bandwidth-hungry live video, on the other hand, will call for an alternate networking technology. Modern cellular network gateways will be able to accommodate both technologies at the same time.

Note that legacy sensors needn’t be left out. Manufacturers are producing battery-powered network nodes, such as the Wzzard Intelligent Edge Nodes from B&B Electronics, that can connect to existing devices and provide them with wireless mesh networking capabilities as well as a communications path to the network gateway.

Smart gateways

The most useful network gateways can connect to everything from Modbus and serial devices to WiFi and/or SmartMeshIP, and keep the data moving via either wired or cellular data connections. Where wired connections are available they’re usually going to be the preferred choice, as they require no cellular data plans. So parking system network gateways are often placed at locations like entrances and exits. There they can connect to wired devices like security cameras, card readers and digital signage, as well as local wireless networks and the Internet. But the ability to use the cellular networks remains important. The network gateway can be configured for automatic cellular failover if the wired connection should fail. This gives the entire network enhanced resilience and reliability.

In the consumer world, new technologies quickly drive their predecessors out of the picture, but that’s not a luxury that the industrial Internet of Things will be able to afford. The data networking infrastructure that is already in place is far too valuable and far too complex to be casually cast aside. So as the industrial Internet of Things unfolds we will add new layers of sophistication to our existing M2M data networks and we will enhance them with new tools like low power wireless mesh networking and sophisticated cellular network gateways that aggregate, convert and transmit multiple data networking protocols. We will move data across fibre, copper, cellular and wireless connections. We will add smaller, smarter, more capable nodes to our networks, but we will let older equipment remain connected as well. Newer technologies like low power wireless mesh networking won’t eliminate the data networking technologies of the past. They will partner with them and help them retain their value.